Precision Thermal Management For Wind Turbine Component Production

Wind Power Applications

Driving Quality And Efficiency In Next-Generation Wind Technology

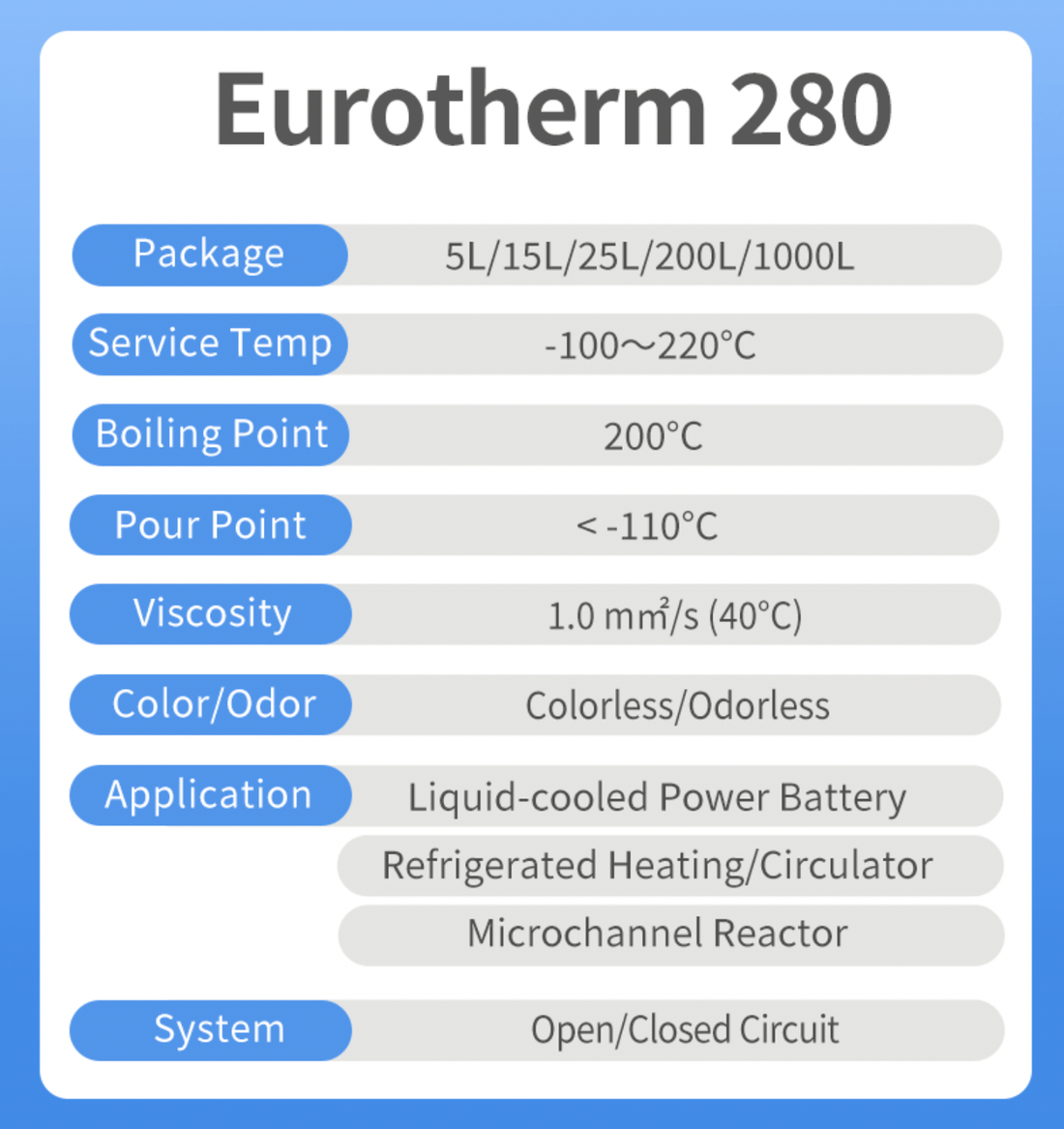

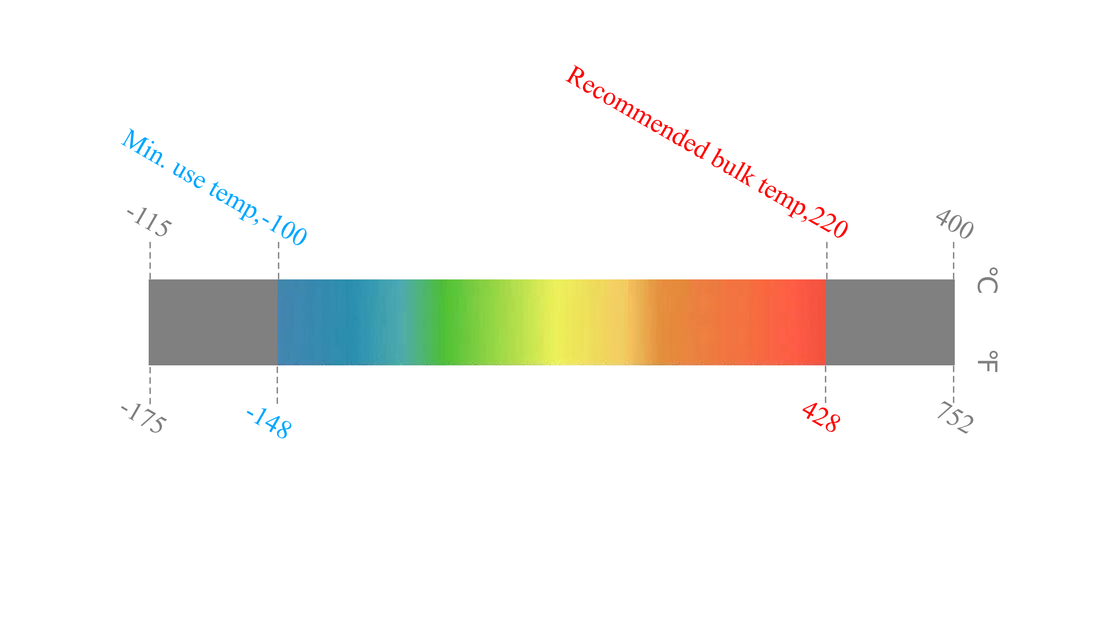

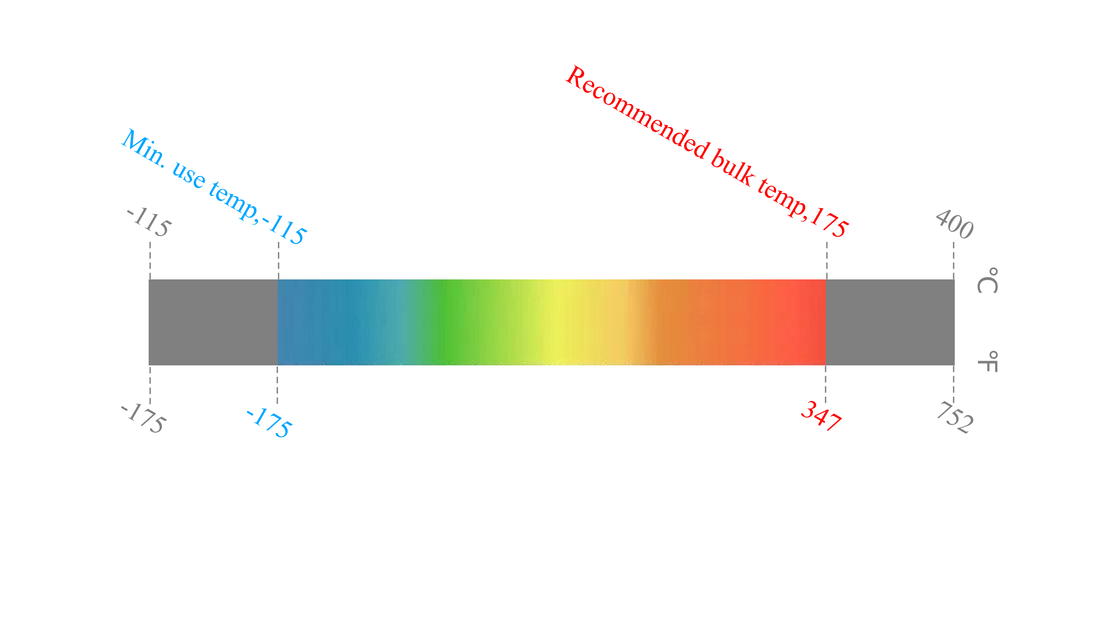

In the rapidly scaling wind energy sector, where blade dimensions exceed 100 meters and production precision defines operational lifespan, thermal control is the invisible foundation of manufacturing excellence. At Chemie Heat Transfer Fluid, our proven solutions—Eurotherm 320 and Eurotherm R1000—deliver the exacting temperature stability essential for wind turbine component fabrication. In blade manufacturing facilities, where composite materials demand precise cure profiles, our fluids circulate through mold heating systems to maintain uniform temperatures during epoxy resin polymerization, eliminating thermal gradients that cause delamination or structural defects. Eurotherm 320's superior heat transfer characteristics ensure rapid thermal response and consistent temperature distribution across large-scale molds spanning 50+ meters, while R1000 provides specialized performance for auxiliary heating circuits and thermal management systems. From controlling cure cycles in autoclave-free production processes to supporting cooling systems in nacelle component manufacturing, Chemie fluids enable manufacturers to achieve faster cycle times, reduce scrap rates, and maintain the structural integrity standards that ensure 25-year turbine operational lifespans—powering the global transition to clean energy with thermal precision.

Recommended Products

-

Xem tất cả